Pen Plating Unit

The most cost effective and fast method of selective coating is pen coating. Selective coating requires masking of parts in conventional rock coating systems. In moss production masking method causes additional labor, time and material cost. Main objective of the pen plating users is to obtain plating quality similar to rock plating. In the application of pencil coating, the power supply and coating pen are the most important factors in the success of the user.

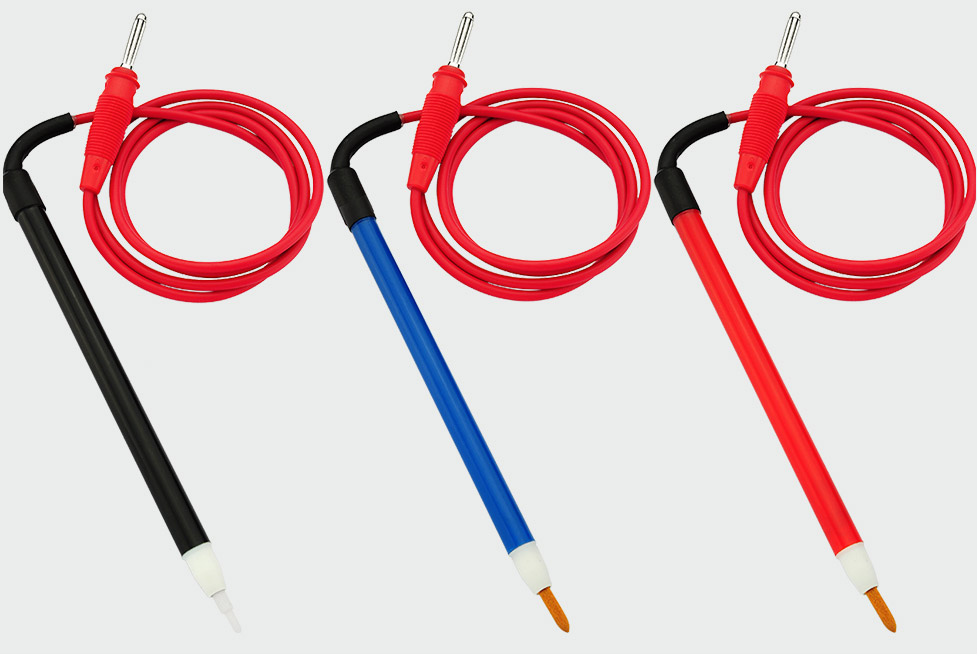

Electrodes Plating Pen

Since the pencil coating chemicals are generally acidic solutions, the parts that transmit the current are made of platinum. In each item, 1 to 2 grams of platinum is used. Platinum surrounding plastic material over time is deformed based on chemical corrosion and high corrections. Our platinum plated titanium pens are plated at the professional titanium anode manufacturer .

ANODES

IAT can supply anodes for the three major plating applications for steel band, namely zinc (EGL), tin (ETL) and chromium (ECL). The first one is predominantly used for the automotive industry, the second and third one are being used in the food industry for cans and in the packaging industry. In all cases oxygen producing anodes are being used, each with its own tailored Iridium Tantalum Mixed Metal Oxide coating.

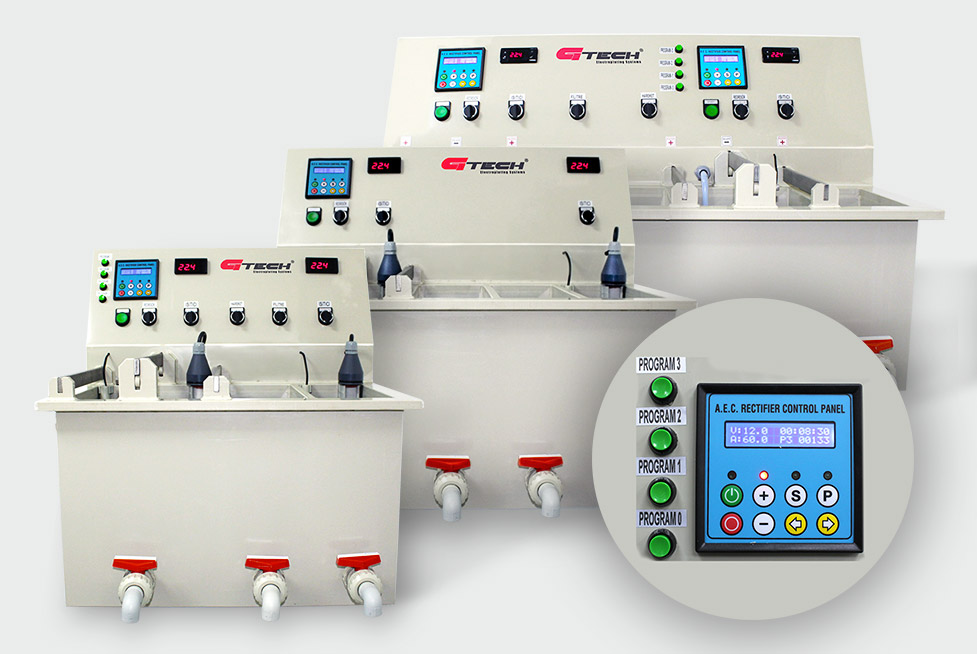

GALVANIC PLANTS

- SMPS Power Supply

- Volt and Ampere controlled operation feature

- Digital Timer

- Precision Amps / Minute Counter

- Movable Cathode Bar

- Digital Thermostat Heat Control

- Filtering System

- Unique User Interface

PEN COATING TIPS

Pen coating tips are produced from fiber materials with many varieties and combinations of resins produced in many different properties etc. You can choose us to reach low consumption costs and high quality in the coating of precious metals.